You are here: > Home > Products > Geothermal Coiled Tubing

Geothermal Coiled Tubing

Alloy 825 Geothermal Coiled Alloy Tubing

MEILONG manufactures Seamless Corrosion Resistant Alloy (CRA) Hydraulic Control Line Tubing products for a variety of upstream oil and gas and geothermal applications. MEILONG has extensive experience in producing coiled tubing from duplex, nickel alloy and stainless steel grades to industry and customer-specific requirements.

Control line tubing is available in lengths from 400 feet (122 meters) to 32,808 feet (10,000 meters). Long lengths are possible by utilizing a combination of strip splice and tube-to-tube orbital welds.

Diameters range from 0.125 inches (3.18 millimeters) to 1.75 inches (44.45 millimeters), with wall thicknesses up to 0.160 inches (4 millimeters).

Specialized features can include cold working for higher yield strength, intrusion-free orbital welds and a minimized number of orbital welds. Tubing can be coiled onto IPPC-certified wood or metal reels customized to the users’ specifications. Applications include:

- Capillary coiled alloy tubing for chemical injection

- Bare and encapsulated hydraulic control line coiled alloy tubing for subsea safety valves

- Velocity strings, work strings, and steel tube umbilicals

- Geothermal coiled alloy tubing

Available Alloy Grades for Control Line Tubing

Austenitic: 316L

Duplex: S31803/S32205

S32750

Nickel alloy: N08825

N06625

316L Stainless Steel Tubing Features

Close dimensional tolerances

Enhanced mechanical properties

Superior surface finish

High cleanness of inside surface

Controlled ovality, eccentricity

316L Stainless Steel Tube Norms

ASTM A269 / ASME SA269

ASTM A632 / ASME SA632

EN10216-5

Coiled Tubing Process

TIG welded and cold drawn

Seamless and cold drawn

Coiled Tubing Dimension

Outside Diameter: 1/8’’ – 1/2’’ (3.175 mm – 12.7 mm)

Coiled tubing length: up to 32,808 feet (10,000 m)

Tubing with minimum orbital welds reduces the risk of leakages when connecting tubes, and suitable for delivery for customers need.

Single coiled tubing is available

The tubes are delivered with plastic caps for protection from potential contamination during storage.

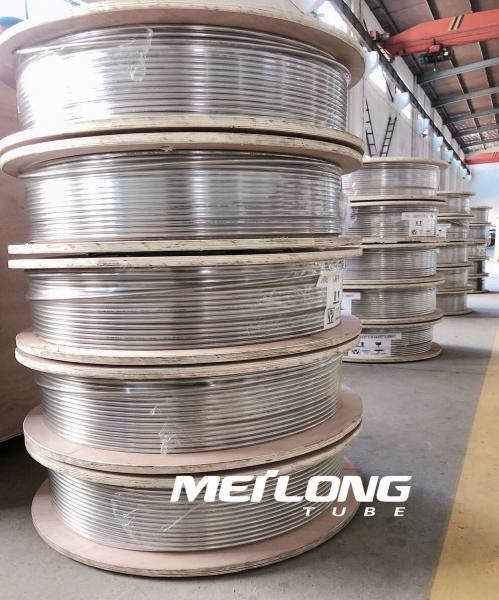

Packing

Coiled tubing is level wound on the spool/reel

Metal reels and marking can be specified by the customer

Application

Control line

Chemical injection line

Electrical line

Multi-line flat pack

Hydraulic line

Tubing encapsulated conductor

Intelligent well completions

Capillary tubing

MEILONG manufactures Seamless Corrosion Resistant Alloy (CRA) Hydraulic Control Line Tubing products for a variety of upstream oil and gas and geothermal applications. MEILONG has extensive experience in producing coiled tubing from duplex, nickel alloy and stainless steel grades to industry and customer-specific requirements.

Control line tubing is available in lengths from 400 feet (122 meters) to 32,808 feet (10,000 meters). Long lengths are possible by utilizing a combination of strip splice and tube-to-tube orbital welds.

Diameters range from 0.125 inches (3.18 millimeters) to 1.75 inches (44.45 millimeters), with wall thicknesses up to 0.160 inches (4 millimeters).

Specialized features can include cold working for higher yield strength, intrusion-free orbital welds and a minimized number of orbital welds. Tubing can be coiled onto IPPC-certified wood or metal reels customized to the users’ specifications. Applications include:

- Capillary coiled alloy tubing for chemical injection

- Bare and encapsulated hydraulic control line coiled alloy tubing for subsea safety valves

- Velocity strings, work strings, and steel tube umbilicals

- Geothermal coiled alloy tubing

Available Alloy Grades for Control Line Tubing

Austenitic: | 316L |

Duplex: | S31803/S32205 S32750 |

Nickel alloy: | N08825 N06625 |

316L Stainless Steel Tubing Features

Close dimensional tolerances

Enhanced mechanical properties

Superior surface finish

High cleanness of inside surface

Controlled ovality, eccentricity

316L Stainless Steel Tube Norms

ASTM A269 / ASME SA269

ASTM A632 / ASME SA632

EN10216-5

Coiled Tubing Process

TIG welded and cold drawn

Seamless and cold drawn

Coiled Tubing Dimension

Outside Diameter: 1/8’’ – 1/2’’ (3.175 mm – 12.7 mm)

Coiled tubing length: up to 32,808 feet (10,000 m)

Tubing with minimum orbital welds reduces the risk of leakages when connecting tubes, and suitable for delivery for customers need.

Single coiled tubing is available

The tubes are delivered with plastic caps for protection from potential contamination during storage.

Packing

Coiled tubing is level wound on the spool/reel

Metal reels and marking can be specified by the customer

Application

Control line

Chemical injection line

Electrical line

Multi-line flat pack

Hydraulic line

Tubing encapsulated conductor

Intelligent well completions

Capillary tubing